Thermal Imaging Surveys and Inspections

Thermal Imaging, Thermography, Infrared (IR)

What is Thermal Imaging?

Thermal imaging is a unique tool that uses the infrared portion of the light spectrum that is invisible to the naked eye. Infrared (IR), Thermography, or Thermal scanning, as it is sometimes called, allows the user to see one’s environment with or without any visible illumination or light.

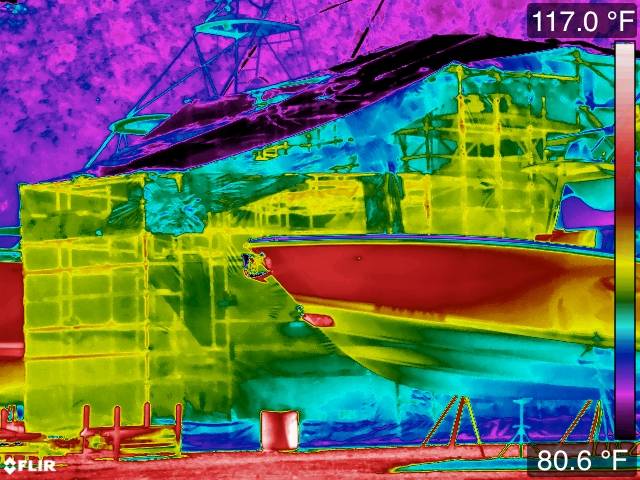

All objects over absolute zero give off a certain amount of thermal radiation. Thermal imaging provides a way to observe temperature anomalies in any machine or object, living, natural, or manmade even in solids like wood, fiberglass, aluminum, and steel.

Thermal imaging or thermography is used by multiple sectors such as law enforcement and security, military, firefighting, medicine, scientific research, air and sea navigation, and marine surveying. IR is especially useful for predictive/preventative maintenance, new construction, and post laminate/structural repairs.

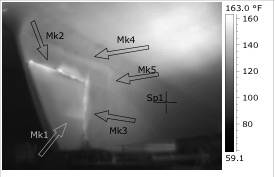

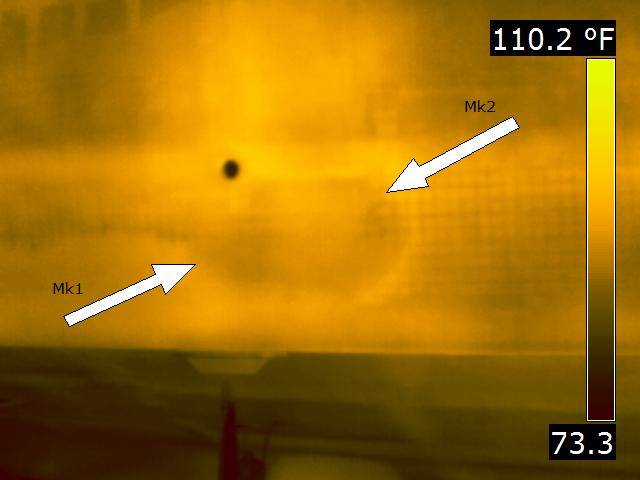

Thermal imaging cameras provide a non-destructive, environmentally friendly way to see temperature differentials in an object to verify such things as electrical and mechanical failures, structural design, delamination (disbanding), damage, voids, structural location, and to locate moisture intrusion.

I currently use the Teledyne FLIR T865, FLIR T640, and FLIR E75-42 which have High Thermal Resolution (640 x 480 and 320 x 240), Currently Calibrated with built-in Digital Cameras and wide-angle lenses to give the best comparison shot(s) and reports to our clients. For a different aspect, we also use DJI Mavic Pro and Phantom 3 Advanced Drones for aerial imaging.

FOR A SAMPLE REPORT PLEASE SEND ME AN EMAIL:

[email protected]

Benefits of Thermal Imaging:

Thermal imaging has multiple beneficial uses across many industries. Since it is non-contact, the area being analyzed remains unadulterated and everyone remains safe during the inspection.

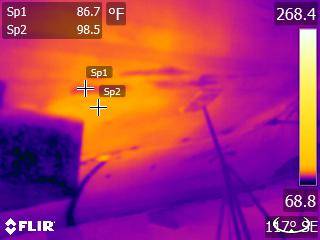

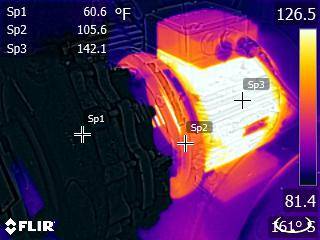

The 2D nature of the testing allows for thermographic profiles to be taken at one or MORE points in a single image.

Thermal imaging is also real-time, fast, and significantly reduces the diagnostic time and final cost of any repair since it is not necessary to disassemble any components being tested. It can pinpoint problems exactly where they occur and even before they are evident to the naked eye.

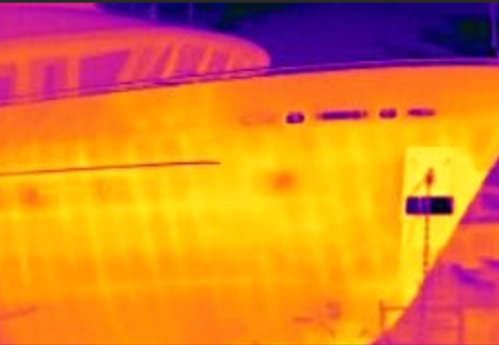

My marine thermal imaging inspections/surveys can include engines, transmissions, tanks, electrical equipment, electronic devices, and hulls to determine if malfunctioning components, leaks, moisture ingress, or disbonding/delamination may exist within the vessel.

Finally, using FLIR Tools +, my thermal imaging reports are clear, helpful, informative, and professional.

What or Where would you use Infrared Imaging?

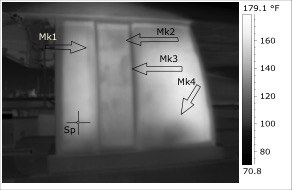

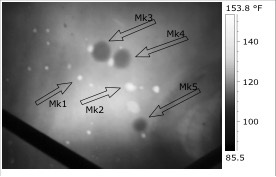

1. Hull and Deck – Infrared (IR) Imaging can indicate anomalies consistent with water intrusion, voids, and disbonding (delamination) within the fiberglass laminate or coring materials.

2. Carbon Fiber, Kevlar Composite – IR imaging is often used on exotic composite vessels due to conductive materials which render moisture meters ineffective. IR imaging can accurately pinpoint laminate deficiencies and moisture ingress points.

3. Engine and Generator – IR imaging can also be applied to motors as they are run during sea trials. Excessive hot spots in the engine blocks, injector lines, exhaust leaks, and cooling systems often reveal internal engine problems that could cause future failures.

4. Electric Systems – “Hot spots” here indicate faulty electrical connections, poor breakers, and faults in wiring that could overheat and catch fire.